When it comes to food manufacturing, sanitation isn’t optional — it’s everything. At Corenco, we design size reduction equipment with one goal in mind: make it easy to use and clean — every single time.

To explore how that works in real production settings, we sat down with Ken Blackwell, Plant Engineer at Sonoma Specialty Foods — a long-time Corenco partner and an expert in culinary manufacturing.

Here’s what he shared about the experience, efficiency, and sanitation reliability of using Corenco machines every day.

What It’s Like on the Production Floor

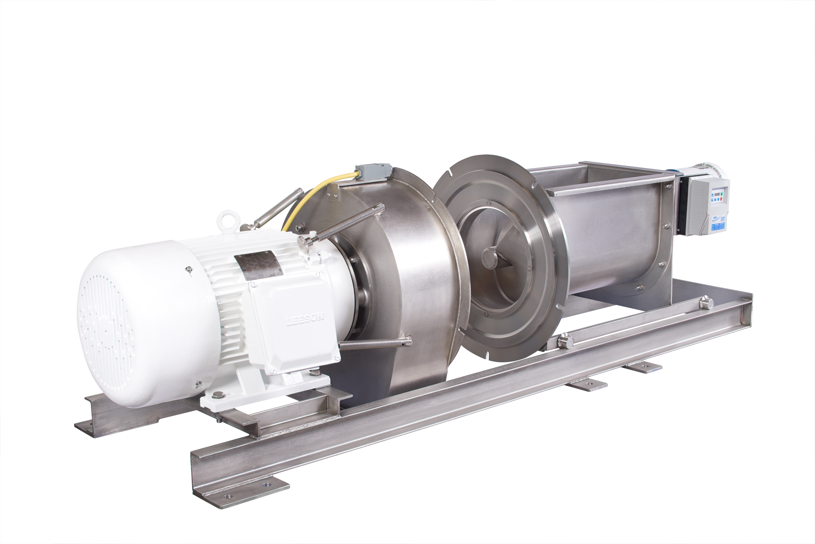

Ken’s team processes large volumes of ingredients like garlic, onions, and vegetables for soups and sauces. They rely on Corenco’s M15 10HP size reduction unit for high-throughput performance, and — importantly — for fast and thorough cleaning and sanitation.

“In terms of breakdown, just a couple minutes to expose all the parts. No tools. Screens come out. Everything opens up.”

Whether cleaning in place or running parts through an industrial dishwasher, their process is straightforward, repeatable, and aligned with food safety standards — thanks to NEMA 4X-rated, washdown-ready design.

Real Culinary Training Meets Real Engineering

Sonoma Specialty Foods is staffed by chefs — and it shows. With culinary degrees and deep production knowledge, the team understands both the science and the art of flavor preparation. Their expectations for equipment are high — and Corenco meets them.

“We run garlic at 205°F all day long with no overheating. The machine holds up beautifully.”

They also tweak voltage to optimize motor performance for torque and efficiency — a sign of engineering fluency and process control.

20+ Years of Trusted Performance

In over two decades of using Corenco machines, Ken’s team has seen minimal issues and zero major failures. That kind of long-term reliability isn’t just anecdotal — it’s earned authority in the field of food equipment manufacturing.

“In 20 years, we’ve had not even a handful of problems. That’s why I’m sitting here today.”

When issues do arise, he knows who to call — and gets immediate support.

Designed for Safety, Backed by Support

Corenco’s equipment is built for total transparency and control. With easy visual access to all parts, defects or contamination risks are immediately visible and fixable.

“If there’s ever a nick or a thing, we see it and fix it right then and there.”

That’s not just good practice — it’s essential for compliance, safety, and consumer confidence.

Garlic in, Garlic Out — With Precision

Using a quarter-inch shredder screen, peeled garlic cloves are processed at high speeds with virtually unlimited throughput, thanks to the strength of the M15 system.

The key? Metering the product properly and respecting the process:

“How you meter product in defines how clean a product you get out. We can’t just jam 250 pounds in at once. That’s part of the recipe.”

Clean Design Is Smart Design

At Corenco, we don’t just build equipment — we build tools for safe, scalable food production. Sonoma Specialty Foods’ success is a powerful example of how cleanability, durability, and professional support come together to fuel real results.

📞 Call us at: 1-888-267-3626

🌐 Visit our Testing Page: Corenco Product Testing

📧 Email: neil@corenco.biz

📱 Call or text Neil Gorsuch at: 707-921-8182

At Corenco, we understand that optimizing your product’s processing efficiency is critical to your success. That’s why we offer Free Comprehensive Product Testing Services, providing businesses with expert insights and real-world data to refine their operations

CLICK HERE TO GET YOUR FREE PRODUCT TEST

With over 40 years of industry experience, Corenco has helped companies across various sectors improve their grinding and processing techniques. Our expert team ensures that your product is tested under real operating conditions using state-of-the-art industrial equipment, allowing you to make informed decisions about your production process.

This limited-time opportunity allows you to experience firsthand how Corenco’s advanced machinery can enhance your processing efficiency, reduce waste, and optimize throughput.

Our testing process delivers tangible benefits, as highlighted by Brent Jonkman from Van Drunen Farms:

“After testing with Corenco, they were able to determine how much horsepower was required to meet and exceed our processing rate….thank you Corenco!”

This kind of precision ensures that you invest in the right equipment with confidence and clarity.

Take advantage of this no-cost opportunity to improve your processing efficiency.

📞 Call us at: 1-888-267-3626

🌐 Visit our Testing Page: Corenco Product Testing

📧 Email: neil@corenco.biz

📱 Call or text Neil Gorsuch at: 707-921-8182

Corenco’s expertise ensures that your product testing is conducted with precision and reliability, helping you achieve the best possible results. Don’t miss this opportunity to gain actionable insights and enhance your production capabilities.

The concept of size reduction plays a crucial role in food processing. By understanding and implementing the principles of size reduction, food manufacturers are able to achieve desired product characteristics and enhance overall food quality. In this article, we will explore the definition of size reduction in food processing, the science behind it, the role it plays in different food processing techniques, its benefits, and the key equipment used.

Size reduction, also known as comminution, refers to the process of reducing the particle size of food ingredients or products. It involves breaking down large particles into smaller, more manageable sizes. This can be achieved through various methods such as grinding, milling, cutting, chopping, or blending.

Size reduction plays a crucial role in various industries, including pharmaceuticals, mining, and agriculture. In pharmaceuticals, it is essential for creating medications with specific dosages and properties. In mining, size reduction is used to extract valuable minerals from ore by crushing it into smaller pieces. In agriculture, it is employed to process feed for livestock or create powdered forms of fertilizers for better absorption.

In food processing, size reduction involves reducing the particle size of ingredients or products to achieve desired characteristics such as better texture, improved dispersion, or enhanced flavor release. It is a fundamental step in many food manufacturing processes.

Various factors influence the choice of size reduction method in food processing, including the initial particle size, desired final particle size, and the properties of the material being processed. For example, delicate herbs may require gentle milling techniques to avoid damaging their volatile oils, while hard grains may need high-impact grinding to achieve the desired fineness.

Size reduction is grounded in the principles of physics and material science. It involves applying mechanical forces to break down the cohesion between food particles. When a force is applied, the particles experience stress, leading to fractures and the formation of new surfaces. This process of breaking and fracture requires energy input, which is typically supplied through mechanical means such as grinding or cutting.

Particle size distribution is a critical parameter in size reduction processes, as it impacts the product’s flow properties, dissolution rate, and overall quality. Understanding the relationship between energy input, particle size, and processing conditions is essential for optimizing size reduction processes in food manufacturing.

Size reduction plays a vital role in various food processing techniques, allowing manufacturers to create products with consistent texture, improved flavor, and enhanced functionality. Let’s explore its significance in baking, meat processing, and beverage production.

In baking, size reduction is essential for achieving the desired texture and uniformity in dough preparation. By reducing the particle size of dry ingredients such as flour, sugar, and leavening agents, bakers ensure even distribution and proper incorporation of these components. This results in a well-mixed batter or dough that bakes consistently and produces the desired texture and structure.

Furthermore, size reduction in baking also affects the final appearance and mouthfeel of the baked goods. When ingredients are finely ground, they create a smoother texture, resulting in a more visually appealing and pleasant eating experience. Additionally, the smaller particle size allows for better hydration, leading to improved moisture retention and a softer, more tender crumb.

In the meat processing industry, size reduction techniques are employed to transform raw meat into various forms such as ground meat, sausages, or meat patties. Grinding or chopping the meat helps improve its texture, reduce cooking time, and enhance flavor absorption. Additionally, it allows for the incorporation of other ingredients and seasonings, ensuring a well-blended and tasty final product.

Moreover, size reduction in meat processing also contributes to food safety. By reducing the meat’s particle size, the surface area exposed to heat during cooking increases, ensuring thorough cooking and eliminating potential pathogens. This is particularly important in products like sausages, where the meat is ground and mixed with other ingredients, as it ensures the entire product reaches the desired temperature for safe consumption.

In beverage production, size reduction plays a significant role in extracting flavors from ingredients, such as fruits or herbs, for the production of juices, teas, or infusions. By reducing the particle size, the surface area available for flavor extraction increases, resulting in a more robust and flavorful beverage. Size reduction is also crucial in the production of powdered drink mixes, where fine grinding ensures easy dissolution and a uniform taste experience.

Furthermore, size reduction in beverage production affects the overall sensory experience. When ingredients are finely ground, they release their flavors more readily, resulting in a beverage with a more pronounced aroma and taste. This is particularly important in the production of herbal teas or infusions, where the extraction of delicate flavors and aromas is key to creating a satisfying and enjoyable beverage.

The implementation of size reduction techniques in food processing offers several benefits that positively impact the overall quality, efficiency, and consumer experience. Let’s explore some of these benefits.

Size reduction ensures the uniform distribution of ingredients and flavors, resulting in products with consistent taste and texture. By reducing particle size, manufacturers can achieve homogeneity and improved sensory characteristics in their food products.

Furthermore, the process of size reduction can also help in extending the shelf life of food products. By breaking down ingredients into smaller particles, the surface area exposed to air and moisture is increased, which can lead to faster evaporation of moisture and oxidation of fats. This can result in a longer-lasting product that maintains its quality and freshness for an extended period.

Smaller particle sizes in food products enhance nutrient release and absorption in the human body. By increasing the surface area-to-volume ratio, the digestion process becomes more efficient, leading to better nutrient absorption and bioavailability.

In addition to improved nutrient absorption, smaller particle sizes can also contribute to a more enjoyable eating experience. Foods with finer textures are often perceived as more palatable and easier to consume, especially for individuals with dental issues or swallowing difficulties. This can broaden the consumer base for food products that undergo size reduction processes.

Size reduction increases the efficiency of food processing operations by reducing processing time and energy requirements. By breaking down ingredients into smaller particles, the overall mixing, blending, and cooking processes become faster and more efficient.

Moreover, the use of size reduction techniques can also lead to a reduction in food waste during processing. By ensuring that ingredients are finely processed and utilized effectively, manufacturers can minimize losses and maximize the yield of their production processes. This not only benefits the bottom line but also aligns with sustainable practices in the food industry.

A variety of equipment is used for size reduction in food processing, catering to different needs and product requirements. Let’s take a look at some commonly used equipment.

Grinders and mills are widely used in food processing to reduce the particle size of dry and wet ingredients. They utilize mechanical forces, such as crushing, grinding, or shear, to break down food particles into smaller sizes. Examples of grinders and mills include hammer mills, ball mills, and roller mills.

Blenders and mixers are essential tools for size reduction in food processing. They are commonly used to blend and mix ingredients, ensuring uniformity and homogeneity in the final product. Blenders can be employed to create smooth purees or pastes, while mixers are used for thorough incorporation of ingredients.

Cutting and chopping tools, such as knives, slicers, and dicers, play a vital role in size reduction, particularly in meat processing and vegetable preparation. These tools allow for the precise and controlled reduction of the particle size, resulting in products with the desired texture and consistency.

Additionally, in the world of food processing, there are other specialized equipment that aid in size reduction. One such equipment is the extruder. An extruder is commonly used in the production of snacks and cereals. It works by forcing the food material through a small opening, which results in the expansion and shaping of the product. This process not only reduces the particle size but also imparts unique textures and shapes to the final product.

Another important equipment used for size reduction is the homogenizer. Homogenizers are commonly used in the dairy industry to break down fat globules into smaller sizes, resulting in a smoother and more uniform product. This process is crucial in the production of products like milk, cream, and ice cream, where a consistent texture is desired.

In conclusion, size reduction is a critical aspect of food processing, facilitating the production of high-quality, consistent, and nutritionally optimized food products. By understanding the concept, science, and benefits of size reduction, food manufacturers can leverage various techniques and equipment to improve efficiency, enhance product characteristics, and ultimately provide consumers with enjoyable and nutritious food experiences.

In recent years, the use of hammer mills in food processing has become increasingly prevalent, particularly in the juice industry. These powerful machines have revolutionized the way food materials are broken down, resulting in enhanced juice extraction and improved product quality. However, their impact goes beyond the processing stage, with economic and environmental considerations coming into play as well.

Before delving into the impact of hammer mills on food processing, it is crucial to understand how these machines operate. Hammer mills are mechanical devices used to grind or crush various materials, such as grains, fruits, or vegetables, into smaller particles. They consist of a rotating shaft with free-swinging hammers that pulverize the feed material upon contact.

Hammer mills have been an integral part of food processing for centuries, evolving from simple hand-operated devices to highly efficient and automated machines. Their ability to reduce the size of materials plays a vital role in various industries, including agriculture, pharmaceuticals, and manufacturing.

The efficiency of hammer mills lies in their ability to generate high-speed impact forces. As the feed material enters the grinding chamber, the rotating hammers strike it with substantial force, breaking it down into smaller particles. The size reduction occurs through a combination of impact, shear, and attrition forces.

The impact force is the primary mechanism responsible for breaking the material into smaller pieces. The hammers, moving at high speed, collide with the feed material, transferring their kinetic energy and causing fractures. Shear forces come into play when the material is caught between the hammers and the grinding chamber’s walls, resulting in further fragmentation. Attrition forces, on the other hand, occur due to the rubbing and grinding action between the particles themselves.

Hammer mills comprise several essential components that facilitate their function. These include the feed hopper, the grinding chamber, the rotor, and the screens. The feed material is introduced through the hopper and distributed evenly across the grinding chamber. The rotating rotor, equipped with hammers, applies the necessary force to break down the material, while the screens control the size of the final product.

The feed hopper is designed to ensure a steady and controlled flow of material into the grinding chamber. It prevents overloading and ensures that the material is evenly distributed, maximizing the efficiency of the grinding process. The size and shape of the hopper may vary depending on the specific application and the type of material being processed.

The grinding chamber is where the actual size reduction takes place. It is a cylindrical or rectangular space enclosed by sturdy walls that can withstand the impact forces generated during operation. The walls of the grinding chamber are often lined with replaceable wear-resistant plates to prolong the machine’s lifespan and maintain optimal performance.

The rotor, a central component of the hammer mill, is responsible for the rotational motion that drives the hammers. It is usually made of high-strength steel and designed to withstand the repetitive impact forces. The number, size, and arrangement of the hammers on the rotor can vary, depending on the desired particle size and the characteristics of the material being processed.

The screens in a hammer mill play a crucial role in controlling the size of the final product. They are perforated plates or wire mesh screens that allow particles of a certain size to pass through while retaining larger particles for further grinding. By selecting the appropriate screen size, operators can achieve the desired particle size distribution and ensure consistent product quality.

In conclusion, hammer mills are versatile machines that have revolutionized the food processing industry. Their ability to grind and crush various materials into smaller particles has made them indispensable in a wide range of applications. Understanding the basic principles and key components of hammer mills is essential for optimizing their performance and achieving desired outcomes.

Hammer mills play a crucial role in the food processing industry, particularly in the juice production process. Their impact can be seen in two main aspects: breaking down the food materials and enhancing juice extraction.

Food materials used in juice production often have a fibrous or tough structure, such as fruits or vegetables. Hammer mills efficiently break down these materials, reducing their size and softening their texture. This process not only facilitates subsequent juice extraction but also improves the overall product consistency and quality.

When it comes to breaking down food materials, hammer mills are designed with precision and efficiency in mind. The hammers inside the mill rotate at high speeds, striking the food materials with force. This impact breaks down the fibers and tough structures, transforming them into smaller particles that are easier to handle and process.

Moreover, hammer mills offer versatility in terms of the desired particle size. By adjusting the speed and screen size of the mill, operators can control the final product’s texture and consistency. This flexibility allows food processors to tailor their products to meet specific market demands and consumer preferences.

Additionally, the breaking down of food materials by hammer mills helps to unlock the full potential of the ingredients. By breaking down the cellular structure, the nutrients and flavors are released, enhancing the overall taste and nutritional value of the juice.

The size reduction achieved by hammer mills significantly increases the surface area of the food particles. This enlarged surface area allows for better extraction of juice during the subsequent pressing or squeezing processes. As a result, hammer mills contribute to higher juice yields and improve overall production efficiency.

During the juice extraction process, the broken down food materials are subjected to pressure, either through pressing or squeezing. The increased surface area resulting from the hammer mill’s size reduction process allows for more efficient extraction of the juice. This means that a larger volume of juice can be obtained from the same amount of food materials, maximizing the yield and reducing waste.

Furthermore, the enhanced juice extraction achieved by hammer mills leads to improved product quality. The extracted juice contains a higher concentration of flavors, nutrients, and natural colors, resulting in a more vibrant and flavorful final product. This is particularly important in the juice industry, where consumers seek products that are not only delicious but also packed with essential vitamins and minerals.

Moreover, the efficiency of hammer mills in enhancing juice extraction contributes to overall production efficiency. By obtaining higher juice yields, food processors can optimize their production processes and reduce costs. This increased efficiency allows for higher output and faster production cycles, meeting the growing demand for juice products in a timely manner.

In conclusion, hammer mills are indispensable in the food processing industry, specifically in juice production. Their ability to break down food materials and enhance juice extraction plays a vital role in improving product consistency, quality, and overall production efficiency. With their precision and versatility, hammer mills continue to revolutionize the way food materials are processed and juice is extracted, ensuring that consumers can enjoy delicious and nutritious juice products.

Hammer mills have long been recognized for their undeniable benefits in food processing. These versatile machines are capable of efficiently grinding a wide range of materials, making them a popular choice in the industry. However, concerns regarding their impact on juice quality have been raised, prompting further investigation into their effects.

Two main aspects warrant consideration when evaluating the influence of hammer mills in juice processing: the effect on nutrient retention and the impact on juice clarity and color.

One potential concern is the loss of nutrients during the grinding process. Hammer mills generate heat due to friction, which may lead to the degradation of certain heat-sensitive nutrients. However, it is important to note that the extent of nutrient loss can be minimized through careful control of the grinding parameters and processing conditions.

By adjusting factors such as the speed of the hammer mill, the size of the screen, and the duration of the grinding process, operators can optimize nutrient retention. Additionally, implementing cooling mechanisms during the grinding process can help mitigate the heat generated, further preserving the nutritional value of the juice.

Furthermore, advancements in technology have led to the development of innovative hammer mill designs that incorporate features specifically aimed at minimizing nutrient loss. These designs prioritize efficient grinding while also prioritizing the preservation of vital nutrients, ensuring that the final product retains its nutritional value.

Another consideration is the potential alteration of juice clarity and color caused by the grinding process. Hammer mills, by their nature, can introduce fine particles and suspended solids into the juice, which may affect its appearance.

However, it is important to note that modern hammer mills are equipped with advanced filtration systems that effectively remove these unwanted particles. By employing appropriate filtration techniques, such as centrifugation or sedimentation, operators can ensure that the juice maintains its pristine clarity.

Furthermore, optimizing process parameters, such as the speed and duration of the grinding process, can help minimize the introduction of fine particles into the juice. By carefully controlling these variables, operators can achieve a balance between efficient grinding and maintaining the desired clarity and color of the juice.

Additionally, advancements in hammer mill technology have led to the development of specialized screens and sieves that further enhance the clarity and color of the juice. These screens are designed to efficiently separate the desired juice from any unwanted particles, resulting in a visually appealing final product.

In conclusion, while concerns regarding the impact of hammer mills on juice quality are valid, it is important to recognize that these concerns can be effectively addressed through proper control of grinding parameters, the use of advanced filtration techniques, and the implementation of innovative hammer mill designs. By employing these strategies, operators can ensure that the juice retains its nutritional value and maintains its desired clarity and color, making hammer mills a valuable tool in the food processing industry.

When evaluating the impact of hammer mills on food processing, it is essential to consider the economic implications. Two key factors come into play: cost-benefit analysis and efficiency and productivity gains.

Implementing hammer mills in food processing operations involves initial capital investment. However, the cost can be justified by considering long-term benefits, such as improved juice extraction, enhanced product quality, and reduced manual labor requirements. Conducting a comprehensive cost-benefit analysis enables juice producers to make informed decisions regarding the adoption of hammer mills.

Hammer mills offer significant efficiency and productivity gains in food processing. Their ability to process larger volumes of feed material in a shorter time enhances overall productivity. Additionally, the consistent and homogeneous size reduction achieved by hammer mills improves the downstream processes, resulting in a streamlined production line and enhanced operational efficiency.

Alongside the technical and economic aspects, safety and environmental considerations play a crucial role in the utilization of hammer mills in food processing.

Due to their mechanical nature, hammer mills require appropriate safety measures to ensure operator and equipment safety. These measures may include protective guarding, emergency stop systems, and regular maintenance and inspection procedures. Implementing these safety protocols is essential to safeguard personnel and prevent accidents during the operation of hammer mills.

It is imperative to assess the environmental impact associated with the use of hammer mills. Factors such as noise pollution, energy consumption, and waste generation should be considered. Implementing energy-efficient systems, noise reduction measures, and proper waste management practices can minimize the environmental footprint of hammer mill operations, aligning with sustainable and responsible business practices.

The Impact of Hammer Mills in the Juice Industry is Undeniable

These powerful machines have transformed the way food materials are broken down, leading to enhanced juice extraction and improved product quality. Furthermore, the economic implications, safety considerations, and environmental aspects associated with hammer mill operations cannot be overlooked. By understanding and addressing these aspects, juice producers can harness the full potential of hammer mills, achieving efficient and sustainable food processing in the juice industry.

In the world of size reduction equipment, hammer mills are undoubtedly one of the most popular machines used by various industries. They are a versatile machine that is capable of grinding, crushing, and pulverizing materials into various sizes. But what exactly are hammer mills and how do they work? In this comprehensive guide, we will explore everything you need to know about hammer mills and their applications.

Before diving into the specifics of hammer mills, it is important to understand the definition and function of these machines.

A hammer mill is a type of grinding machine that is used to shred or crush materials into smaller pieces. It consists of a rotor with swinging hammers that strike the material and break it apart. The size of the final product depends on the size of the openings in the screen or grates at the bottom of the machine.

A hammer mill is a machine used to shred or crush materials into smaller pieces. They are widely used in various industries such as agriculture, food processing, and mining.

The main function of a hammer mill is to reduce the size of the material through repeated blows of hammers. These hammers are attached to a rotor that rotates at high speed, causing the material to be pulverized.

Hammer mills are versatile machines that can be used for a variety of purposes. In the agriculture industry, they are commonly used to grind grains into animal feed. In the food processing industry, they can be used to pulverize spices and herbs for seasoning. In the mining industry, they are used to crush rocks and ores for further processing.

Now that we understand the basic function of hammer mills, let’s take a closer look at their key components.

1. Rotor: The rotor is the main rotating component of the hammer mill. It contains the hammers and provides the necessary power to crush the material. The rotor is usually made of heavy-duty steel to withstand the impact of the hammers.

2. Hammers: The hammers are the striking tools attached to the rotor. They come in various shapes and sizes, depending on the application and desired particle size. Some hammers have a flat surface, while others have a curved or serrated edge to enhance the grinding or shredding process.

3. Screen or Grates: The screen or grates are located at the bottom of the machine and determine the final product size. They control the flow of the crushed material and allow for the desired particle size to pass through. The size of the openings in the screen or grates can be adjusted to achieve different particle sizes.

4. Feed Hopper: The feed hopper is the entry point for the material into the hammer mill. It is designed to ensure a steady and controlled flow of material to the rotor and hammers. The size and design of the feed hopper may vary depending on the specific application and material being processed.

5. Discharge Chute: The discharge chute is where the final product exits the hammer mill. It is designed to direct the crushed material into a collection container or conveyor for further processing or storage.

6. Drive System: The drive system of a hammer mill is responsible for powering the rotor and controlling its speed. It typically consists of an electric motor, a belt or chain drive, and a gearbox or direct drive system. The drive system allows for precise control of the rotor speed, which can affect the particle size and overall efficiency of the grinding process.

7. Safety Features: Hammer mills are equipped with various safety features to protect the operator and prevent accidents. These may include safety guards, emergency stop buttons, and interlock systems that prevent the machine from operating when certain conditions are not met.

Overall, hammer mills are reliable and efficient machines that play a crucial role in many industries. Their ability to reduce the size of materials and create uniform particles makes them valuable tools for processing and manufacturing. Whether it’s grinding grains for animal feed or pulverizing rocks for mining, hammer mills are an essential part of the process.

When it comes to grinding and crushing materials, hammer mills are a popular choice due to their versatility and efficiency. There are two main types of hammer mills: high-speed and low-speed hammer mills. Let’s take a closer look at each.

High-speed hammer mills are known for their ability to handle fine-grinding applications in various industries. These industries include the feed, oilseed, and biomass industries. The key feature of high-speed hammer mills is their ability to operate at a very high rotational speed, resulting in rapid and efficient impact on the material being processed.

One of the primary applications of high-speed hammer mills is in the processing of animal feed and agricultural products. These mills are capable of grinding and crushing grains, such as corn, wheat, and barley, into smaller particles, making them more digestible for livestock. Additionally, high-speed hammer mills are often used in the production of ethanol and other biofuels, where they play a crucial role in breaking down biomass materials into smaller, more manageable sizes.

Low-speed hammer mills, on the other hand, are specifically designed to handle tough and fibrous materials. These mills operate at a relatively low rotational speed, which allows for a gentler impact on the material being processed.

The wood industry heavily relies on low-speed hammer mills for processing wood chips, sawdust, and other wood waste materials. These mills are capable of reducing the size of wood materials, making them suitable for further processing or utilization. Whether it’s for the production of particleboard, fiberboard, or other wood-based products, low-speed hammer mills play a vital role in breaking down the raw materials into smaller, more manageable pieces.

In addition to the wood industry, low-speed hammer mills are also commonly used in the production of paper and cardboard. These mills are capable of grinding and crushing recycled paper and cardboard materials, allowing for their transformation into pulp, which can then be used to produce new paper products.

Overall, both high-speed and low-speed hammer mills have their specific applications and advantages. High-speed hammer mills excel in fine-grinding applications, while low-speed hammer mills are ideal for handling tough and fibrous materials. Regardless of the type, hammer mills continue to be a reliable and efficient solution for various industries in need of size reduction and material processing.

Now that we have covered the different types of hammer mills, let’s dive into their working principles.

Hammer mills are widely used in various industries for grinding and crushing different materials. They operate on the principle of impact, where the rotor rotates at high speed and the hammers attached to it strike the material, causing it to be crushed into smaller particles. The crushed material then passes through a screen or grates at the bottom of the machine, allowing the desired particle size to pass through.

The working principle of a hammer mill is quite simple. Let’s take a closer look at how it works:

Hammer mills are versatile machines that can be used for a wide range of applications. They are commonly used in the agricultural, pharmaceutical, chemical, and mining industries, among others. The size and design of the hammers, as well as the screen or grates, can be customized to meet the specific requirements of different materials and desired particle sizes.

In conclusion, hammer mills are powerful and efficient machines for grinding and crushing various materials. Their working principle, based on impact and pulverization, allows for the production of particles of different sizes. Whether it is for reducing the size of agricultural products, processing minerals, or preparing raw materials for further processing, hammer mills play a crucial role in many industries.

Hammer mills have a wide range of applications across various industries. Let’s explore some of their common uses.

In the agricultural sector, hammer mills are often used for grinding grains, hay, and straw. They are also used for processing crop residues and agricultural by-products into animal feed.

Additionally, hammer mills are used for the production of ethanol from corn and other feed grains. They help break down the cellulosic material, allowing for the extraction of fermentable sugars.

Aside from the agricultural sector, hammer mills are widely used in various industries for size reduction and particle size control.

In the food processing industry, hammer mills are used to grind spices, coffee beans, grains, and other food ingredients into powder or fine particles.

In the mining and minerals industry, hammer mills are used to crush and pulverize ores into smaller particles for further processing.

Operating a hammer mill involves certain safety measures to ensure the well-being of the operators and the proper functioning of the machine.

When operating a hammer mill, it is important to wear the appropriate personal protective equipment (PPE) to prevent injuries. This includes safety goggles, gloves, and hearing protection.

In addition to wearing PPE, operators should follow safety protocols and procedures when operating a hammer mill. This includes ensuring that the machine is properly maintained, using the correct settings for the desired particle size, and avoiding any potential hazards.

Proper maintenance of hammer mills is crucial to ensure their longevity and optimal performance. Let’s explore some maintenance practices and common troubleshooting issues.

Regular maintenance of a hammer mill includes greasing the bearings, inspecting the hammers for wear and tear, and checking the screen or grates for any damage or clogging. It is important to follow the manufacturer’s recommendations for maintenance intervals and procedures.

Some common issues that may arise when operating a hammer mill include excessive noise, uneven particle size distribution, and hammers getting stuck. These problems can often be resolved by adjusting the machine settings, replacing worn-out parts, or cleaning the machine thoroughly.

If the issues persist, it is recommended to consult the manufacturer or a qualified technician for further assistance.

Hammer mills are an essential piece of equipment in various industries for grinding, crushing, and pulverizing materials into smaller particles. Understanding their working principles, types, and applications is crucial for anyone involved in size reduction processes.

By following safety measures and proper maintenance practices, operators can ensure the safe and efficient operation of hammer mills, prolonging their lifespan and optimizing their performance.

Whether you are in the agricultural sector, food processing industry, or mining and minerals industry, hammer mills can be a valuable tool in your operations.

So next time you encounter the need for size reduction, consider the power and versatility of hammer mills.

The food processing industry plays a crucial role in our daily lives by ensuring that the food we consume is safe, nutritious, and readily available. One of the key components of this industry is the use of industrial grinders. These powerful machines are designed to process food ingredients into various forms, ranging from powders and pastes to emulsions and suspensions. In this article, we will take a closer look at the benefits of using industrial grinders in the food processing industry.

1. Enhanced Efficiency

Industrial grinders are designed to efficiently process large quantities of food ingredients in a short span of time. This not only saves valuable time but also increases overall productivity in food processing plants. By automating the grinding process, industrial grinders eliminate the need for manual labor, allowing workers to focus on other important tasks.

2. Consistent Quality

Consistency is essential in the food processing industry. Industrial grinders ensure that the texture, particle size, and consistency of the processed food ingredients remain uniform throughout the production process. This is crucial in maintaining the quality of the final food products and meeting consumer expectations.

3. Versatility

Industrial grinders are incredibly versatile and can handle a wide range of food ingredients. From fruits and vegetables to meat and spices, these machines are capable of grinding various types of ingredients. This versatility allows food processing plants to produce a diverse range of products, catering to different consumer preferences.

4. Waste Reduction

Food waste is a significant concern in the food processing industry. Industrial grinders play a crucial role in reducing waste by effectively grinding and utilizing every part of the food ingredient. By minimizing waste, food processing plants can not only improve their sustainability practices but also reduce expenses associated with waste disposal.

5. Improved Safety

Industrial grinders are designed with safety in mind. These machines are equipped with various safety features, such as emergency stop buttons and protective covers, to ensure the well-being of workers. Additionally, industrial grinders eliminate the risk of contamination by grinding food ingredients in enclosed and sanitary environments.

An industrial grinder is a heavy-duty machine specifically designed for commercial use in the food processing industry. Unlike household grinders, industrial grinders are capable of withstanding high volumes of grinding and are built to withstand the rigorous demands of a production environment. These machines are typically equipped with powerful motors, sharp blades, and sturdy construction materials to ensure optimal performance and longevity.

Industrial grinders are available in various sizes and configurations to cater to different processing needs. Some common types of industrial grinders used in the food processing industry include:

– Rotary Grinders: Utilize rotating shafts with blades to effectively grind food ingredients. These grinders are commonly used for grinding meat and other solid ingredients.

– Hammer Mills: Utilize high-speed rotating hammers to pulverize food ingredients into fine powders. Hammer mills are often used for grinding grains, spices, and dried herbs.

– Colloid Mills: Utilize high-speed rotor and stator assemblies to emulsify, disperse, and grind food ingredients into fine pastes and suspensions. Colloid mills are commonly used for processing nut butters, sauces, and dressings.

An industrial food grinder is a specific type of industrial grinder designed for processing food ingredients. These machines are specially engineered to meet strict food safety standards and possess features that enhance food processing efficiency. Industrial food grinders are widely used in food processing plants, restaurants, and commercial kitchens.

Industrial food grinders offer numerous benefits over traditional household grinders, such as:

– Large Capacity: Industrial food grinders are capable of processing large quantities of food ingredients at once, making them ideal for commercial use where high production volumes are required.

– Speed and Efficiency: Industrial food grinders are equipped with powerful motors and sharp blades, allowing for efficient and rapid grinding of food ingredients.

– Durability: Industrial food grinders are built to withstand heavy usage and are constructed using durable materials, ensuring long-lasting performance even in demanding environments.

– Food Safety: Industrial food grinders are designed to meet strict food safety regulations, ensuring that processed food ingredients are free from contamination and safe for consumption.

In conclusion, industrial grinders play a crucial role in the food processing industry by enhancing efficiency, maintaining consistent quality, offering versatility, reducing waste, and improving safety. These powerful machines are used to process a wide range of food ingredients, ensuring that the final food products meet consumer expectations. Industrial grinders, including industrial food grinders, are specifically designed for commercial use and are equipped with features that enhance food processing efficiency and safety. By utilizing industrial grinders, the food processing industry can achieve higher productivity, reduce waste, and deliver high-quality food products to consumers.

🌐 Nut-processing with industrial grinders is taking center stage, offering a nutritious and allergen-friendly alternative to traditional dairy. With the aid of state-of-the-art industrial grinders, the global peanut butter market soared to $3 billion in 2017, and the love for nut products keeps growing. 📈 What brand of industrial grinder should I use for nut paste? A Corenco of course!

🥜 Why the Craze for Nut Butters?

When nuts undergo the transformative process of grinding with industrial grinders, they become more accessible, digestible, and versatile for daily consumption. Nut butters, whether almond, cashew, or hazelnut, are not just convenient; they’re nutrient powerhouses. Packed with fiber, micronutrients, anti-inflammatory fatty acids, and protein, they’re the go-to healthy snack, averaging 190 calories, 16g of fat, and 6g of protein in a 2-tablespoon serving. 🌰🥄

🥛 Unveiling Nut Milk: A Dairy Alternative

Nut milk, the dairy-free delight, comprises 5%-15% nut matter, usually almonds, soy, or cashews, blended with water, sweeteners, and thickeners using industrial grinders. Homemade variations boast a richer nut concentration, with a simple recipe of 1 1/2 cups water and three tablespoons nut paste processed with industrial grinders. The result? Homemade nut milk with approximately 12% nut matter—pure goodness without additives. 🌰🥛

🔥 Dry Roasting: Batch vs. Continuous

The journey of nuts from raw to roasted is crucial. Dry roasting, whether by batch or continuous methods using industrial grinders, sets the stage for flavorful nut products. Batch roasting in large ovens or continuous processing with a streamlined approach caters to different production goals. Batch roasting offers flexibility for nut blends, considering varying moisture levels in different nuts. On the flip side, continuous roasting is swift, less labor-intensive, and ensures uniform roasting for a consistent product. 🥜🔥

⚙️ Granulating: A Niche Art

Granulating, a specialized technique in nut processing, involves turning nuts into a granular form—think ice cream cone toppings. Achieving uniform size without creating a paste is the key. While few technologies cater to this niche, dicers and industrial Angle disintegrators prove handy in the granulating process. 🔄

🛠️ Investing Wisely in Industrial Grinders for Nut Processing

The backbone of seamless nut processing lies in quality equipment. Collaborating with industry leaders like Corenco ensures access to durable and high-quality industrial grinders for nut processing. Invest wisely for a nutty journey that delights taste buds and meets the highest standards. 🌰

Curious to learn more about Nut Butter Processing and identify the ideal machines for your needs? Reach out to Corenco today. Our dedicated team is ready to assist you on your journey to optimized size reduction processes. What brand of industrial grinder should I use for nut butters? A Corenco of course!

If you work in an industry that requires the processing of raw materials into finished products, then industrial grinders are likely a crucial component of your operation. With so many different types and models of industrial grinders on the market, however, choosing the right one can be a daunting task. In this comprehensive guide, we’ll take a closer look at industrial grinders, including their key components and the various types available, as well as the factors you should consider when choosing the right grinder for your needs.

Industrial grinders are machines designed to process a wide variety of materials, including plastics, rubber, metals, and more. Essentially, the purpose of an industrial grinder is to reduce the size of raw materials and turn them into smaller, more manageable pieces that can be easily handled, transported, and processed further if necessary.

Industrial grinders are used in a variety of industries, including manufacturing, recycling, and mining. They are essential for breaking down large materials into smaller, more manageable pieces that can be used to create new products or materials.

Despite the many different types of industrial grinders available, most share some common components that are essential to their operation. These components include:

Industrial grinders are complex machines that require regular maintenance to keep them running smoothly. This includes cleaning, lubricating, and replacing parts as necessary.

There are many different types of industrial grinders available, each designed for specific materials and applications. Some of the most common types of industrial grinders include:

Choosing the right type of industrial grinder for a specific application requires careful consideration of factors such as the type of material being processed, the desired end product, and the amount of material being processed.

Industrial grinders are essential tools for many manufacturing and processing operations. They are used to break down materials into smaller, more manageable pieces, making them easier to transport, store, or use in other processes. However, not all industrial grinders are created equal, and choosing the right one for your operation requires careful consideration of several factors.

The first and most important factor to consider when choosing an industrial grinder is the material you’ll be processing. Different materials have different properties and require different types of grinders to process efficiently. For example, plastics and rubber tend to be softer and more flexible, while metals are harder and more brittle. Other materials, such as wood, may require specialized grinders that are designed to handle the unique challenges of processing organic materials.

When selecting a grinder, it’s important to consider the size, shape, and consistency of the material you’ll be processing. Some grinders are better suited for grinding large, bulky materials, while others are designed for finer, more delicate materials. Choosing the wrong type of grinder can result in inefficient processing, damage to the material, or even damage to the grinder itself.

The next factor to consider is the required production capacity for your operation. Industrial grinders come in a range of sizes and are designed to process different amounts of material per hour. Make sure you choose a grinder that can keep up with your production needs without being overworked or underutilized.

It’s also important to consider the potential for future growth or changes in your operation. If you anticipate an increase in production capacity in the near future, it may be wise to invest in a larger grinder now to avoid the need for costly upgrades or replacements down the line.

Another important consideration is the size of the grinder and the amount of space you have available in your facility. Industrial grinders come in a range of sizes, from small tabletop models to large industrial-sized machines. Make sure you choose a grinder that fits in the space you have available while still meeting your production needs.

You should also consider the layout of your facility and any potential obstacles or constraints that may impact your ability to move the grinder into place. For example, if you need to move the grinder up or down stairs or through narrow doorways, you may need to choose a smaller, more portable model.

Operating an industrial grinder can be expensive, both in terms of energy costs and maintenance and repairs. When choosing a grinder, look for models that are energy-efficient and have low operating costs.

Some grinders may be more expensive upfront but offer significant cost savings over time due to lower energy consumption or reduced maintenance requirements. It’s important to consider the long-term costs and benefits of each grinder option before making a final decision.

Finally, consider the maintenance and repair requirements of the grinder you choose. Industrial grinders can be complex machines that require regular maintenance to continue operating at peak efficiency. Make sure you choose a grinder that is built to last and can stand up to heavy use and frequent maintenance requirements.

You should also consider the availability of replacement parts and the expertise required to perform maintenance and repairs on the grinder. Choosing a grinder with readily available parts and a user-friendly design can help minimize downtime and reduce maintenance costs over time.

By carefully considering these factors and choosing the right industrial grinder for your operation, you can improve efficiency, reduce costs, and ensure optimal processing of your materials.

Industrial grinders are an essential tool in many manufacturing and processing industries. They are used to grind materials into smaller, more manageable pieces, making them easier to transport and process further. Here are some popular types of industrial grinders:

Hammer mills are perhaps the most common type of industrial grinder and are used to grind materials into fine powders. Hammer mills work by using rotating hammers to break apart materials and reduce them in size. They are commonly used in the agricultural industry to grind grains and animal feed, as well as in the mining and construction industries to crush rocks and other materials.

Granulators are another type of industrial grinder and are typically used to process plastics and rubber. Granulators use rotating knives to cut materials into smaller pieces, which are then passed through screens to produce a uniform product. They are commonly used in the plastic manufacturing industry to recycle plastic waste and turn it into new products.

Shredders are industrial grinders that are used to process a wide range of materials, including wood, plastic, and metal. Shredders work by using rotating blades to tear materials apart, producing smaller pieces that can be easily transported and processed further. They are commonly used in the recycling industry to shred and process waste materials, as well as in the manufacturing industry to reduce the size of raw materials.

Pulverizers are industrial grinders that are designed specifically for grinding materials into fine powders. Pulverizers use a combination of rotating blades and screens to grind materials into uniform powders that can be used in a variety of applications. They are commonly used in the pharmaceutical and chemical industries to grind materials into powders for use in medicines and other products.

Ball mills are industrial grinders that are used to grind materials into very fine powders. Ball mills work by rotating a cylinder filled with grinding media, such as steel or ceramic balls, which grind the material down into a fine powder. They are commonly used in the mining and construction industries to grind ores and rocks, as well as in the chemical and ceramic industries to grind materials into powders for use in various products.

Overall, industrial grinders are an essential tool in many industries, helping to reduce the size of materials and make them easier to transport and process further. With a variety of different types of grinders available, there is sure to be a grinder that is perfect for your specific application.

Choosing the right industrial grinder for your needs is essential if you want to ensure that your operation runs smoothly and efficiently. By considering factors such as the material you’ll be processing, production capacity requirements, and energy efficiency, you can find the perfect grinder to suit your needs. Whether you’re grinding plastics, metals, or other materials, there’s an industrial grinder out there that’s right for you.

Industrial grinders play a crucial role in the food processing industry, providing efficient and effective solutions for various grinding needs. In this comprehensive guide, we will explore the functionality, types, selection considerations, maintenance and safety, as well as the impact of industrial grinders on food quality.

Industrial grinders are powerful machines designed to reduce food ingredients into smaller particles, enhancing their usability and aiding in food preparation. These grinders are commonly used in the production of spices, herbs, grains, and other food products.

When it comes to food processing, industrial grinders play a crucial role in ensuring that the ingredients are finely ground to achieve the desired texture and consistency. Whether it’s grinding spices for a flavorful curry or pulverizing grains for baking purposes, these machines are essential in the food industry.

Industrial grinders utilize a rotating mechanism to grind food ingredients. The grinding process involves the interaction between the rotating blades or discs and the food particles, resulting in the reduction of particle size.

These machines are equipped with powerful motors that drive the rotating mechanism, ensuring efficient and consistent grinding. The blades or discs are strategically designed to create a vortex-like motion, pulling the food particles towards the center and grinding them into smaller pieces.

Depending on the desired particle size, industrial grinders offer adjustable grinding settings. This allows food manufacturers to have control over the final product’s texture, ensuring that it meets the specific requirements of their recipes.

Industrial grinders are designed with various features to optimize performance and facilitate efficient food processing. Some key features include adjustable grinding settings, durable construction materials, and user-friendly controls.

One of the key features of industrial grinders is their ability to handle large quantities of food ingredients. These machines are built to withstand heavy-duty usage, making them ideal for commercial food processing facilities.

Furthermore, industrial grinders are often constructed using durable materials such as stainless steel. This ensures that the machines can withstand the rigors of continuous grinding without succumbing to wear and tear. The robust construction also contributes to the longevity of the grinders, reducing the need for frequent repairs or replacements.

In addition to their functionality, industrial grinders are designed with user-friendly controls. This allows operators to easily adjust the grinding settings, monitor the grinding process, and ensure optimal performance. The intuitive interface and clear instructions make it easier for operators to operate the machines efficiently, minimizing the risk of errors or accidents.

Overall, industrial grinders are essential tools in the food processing industry. Their ability to efficiently grind food ingredients into smaller particles not only enhances the usability of the ingredients but also contributes to the overall quality and consistency of the final food products.

When it comes to food processing, having the right equipment is crucial for achieving optimal results. Industrial grinders play a vital role in breaking down food ingredients into smaller, more manageable sizes. There are several types of industrial grinders available in the market, each with its specific features and advantages. Let’s explore some of the commonly used types:

Disc mills, also known as attrition mills, are versatile grinders that use a series of rotating discs to grind food ingredients. These discs can be made of various materials, such as stainless steel or stone, depending on the specific application. One of the key advantages of disc mills is their ability to offer precise control over particle size. By adjusting the gap between the discs, operators can achieve the desired fineness of the final product. Disc mills are commonly used for grinding oily or wet ingredients, making them ideal for applications such as peanut butter production or wet spice grinding.

Hammer mills, as the name suggests, utilize high-speed rotating hammers to pulverize food ingredients into smaller particles. These hammers are attached to a rotor, which spins at a high velocity within a chamber. The food ingredients are fed into the chamber and are repeatedly struck by the hammers until they are reduced to the desired size. One of the key advantages of hammer mills is their ability to handle a wide range of materials. From grains and spices to fibrous materials like meat or vegetables, hammer mills can effectively process them all. Additionally, hammer mills are known for their ability to generate consistent particle sizes, ensuring uniformity in the final product.

Pin mills, also known as universal mills, are specialized grinders that use narrow pins or needles to reduce particle size. These pins are evenly distributed on a rotating disc or plate, which creates a high-speed impact on the food ingredients. Pin mills are often used for fine grinding, where a high degree of particle size reduction is required. They are particularly suitable for fragile or heat-sensitive food ingredients, as the grinding process generates minimal heat. This helps to preserve the quality and integrity of the ingredients, making pin mills a popular choice in industries such as pharmaceuticals or confectionery.

Choosing the right type of industrial grinder for food processing depends on various factors, including the specific application, desired particle size, and the characteristics of the ingredients being processed. By understanding the different types of grinders available and their unique features, manufacturers can make informed decisions to optimize their food processing operations.

Choosing the appropriate industrial grinder for your specific needs is crucial to achieve optimal grinding results. Consider the following factors when selecting an industrial grinder:

Identify the specific requirements of your food processing operation. Consider factors such as desired particle size, processing capacity, and the types of food ingredients you will be grinding.

When assessing your grinding needs, it is important to consider the desired particle size. Different food products may require different particle sizes for optimal results. For example, if you are grinding spices, a fine particle size may be desired to ensure even distribution of flavor. On the other hand, if you are grinding meat for sausage production, a coarser particle size may be preferred to achieve the desired texture.

Processing capacity is another important factor to consider. How much food do you need to process in a given time frame? This will help determine the size and capacity of the industrial grinder you require. If you have a high-volume food processing operation, you will need a grinder that can handle a large amount of food at once to ensure efficient production.

The types of food ingredients you will be grinding also play a role in selecting the right industrial grinder. Some grinders are better suited for specific food products. For example, if you are grinding oily ingredients like nuts or seeds, you may need a grinder that is designed to handle these types of materials without clogging or overheating.

Ensure that the industrial grinder you choose has the appropriate size and capacity to handle your intended workload. Consider factors such as available space, production volume, and future growth potential.

Available space is an important consideration when selecting an industrial grinder. Measure the area where the grinder will be placed to ensure that it fits properly and allows for easy access and maintenance. It is also important to consider the layout of your food processing facility and how the grinder will fit into the overall workflow.

Production volume is another factor to consider when choosing the size and capacity of an industrial grinder. If you have a small-scale operation with low production volume, a smaller grinder may be sufficient. However, if you have a large-scale operation with high production demands, you will need a larger grinder that can handle the workload.

Future growth potential should also be taken into account. If you anticipate your food processing operation expanding in the future, it is wise to choose a grinder that can accommodate increased production needs. Investing in a grinder with room for growth can save you the hassle and expense of upgrading to a larger grinder down the line.

By carefully assessing your grinding needs and considering factors such as desired particle size, processing capacity, available space, production volume, and future growth potential, you can select the right industrial grinder for your specific requirements. This will ensure that you achieve optimal grinding results and maximize the efficiency of your food processing operation.

Regular maintenance and adherence to safety protocols are essential for maximizing the lifespan of your industrial grinder and ensuring a safe working environment. Let’s explore some key considerations:

Implementing a regular maintenance routine is crucial for the optimal performance and longevity of your industrial grinder. Cleaning, lubrication, and inspection of critical components should be included in this routine. By following the manufacturer’s guidelines, you can ensure that your grinder operates at its best.

Cleaning your industrial grinder regularly is important to prevent the buildup of debris and contaminants. This buildup can affect the performance and efficiency of the machine. Use appropriate cleaning agents and tools to remove any residue or dirt.

Lubrication is another crucial aspect of maintenance. Proper lubrication of the moving parts reduces friction and wear, extending the life of your grinder. Consult the manufacturer’s recommendations to determine the appropriate lubricant and frequency of application.

In addition to cleaning and lubrication, regular inspection of critical components is necessary. Check for any signs of wear, damage, or misalignment. Replace any worn-out or damaged parts promptly to avoid further issues and potential breakdowns.

Prioritizing safety measures is of utmost importance when working with industrial grinders. By implementing the following precautions, you can minimize the risk of accidents and injuries:

1. Personal Protective Equipment (PPE): Ensure that all operators and maintenance personnel wear appropriate PPE, including safety glasses, gloves, and hearing protection. These protective measures help safeguard against potential hazards such as flying debris, noise, and hand injuries.

2. Safe Operating Procedures: Establish clear and comprehensive operating procedures for the use of industrial grinders. Train all employees on these procedures and ensure that they understand and follow them diligently. Emphasize the importance of proper machine setup, correct tool usage, and safe work practices.

3. Training and Education: Regularly provide training sessions and educational materials to employees regarding the safe use and maintenance of industrial grinders. Keep them updated on any new safety guidelines or procedures. Encourage open communication and reporting of any safety concerns or incidents.

4. Machine Guards and Safety Features: Ensure that your industrial grinder is equipped with appropriate machine guards and safety features. These include protective enclosures, emergency stop buttons, and safety interlocks. Regularly inspect and maintain these safety devices to ensure their effectiveness.

5. Hazard Identification and Risk Assessment: Conduct regular hazard identification and risk assessment to identify potential hazards associated with the use of industrial grinders. Implement appropriate control measures to mitigate these risks and regularly review and update them as needed.

By following these routine maintenance practices and safety measures, you can maximize the lifespan of your industrial grinder while creating a safe working environment for all employees.

Industrial grinders have a significant impact on the quality of food products, influencing factors such as nutrient retention, texture, and consistency. Consider the following aspects when using industrial grinders:

The grinding process may expose food ingredients to heat and oxygen, leading to potential nutrient loss. Minimize nutrient degradation by selecting an industrial grinder that operates at lower temperatures and with minimal exposure to air.

Industrial grinders allow for precise control over the texture and consistency of ground food ingredients. Adjust the grinding settings to achieve the desired particle size and ensure uniformity in your final product.

Industrial grinders for food processing provide essential grinding solutions for various industries. Understanding their functionality, types, selection considerations, maintenance and safety, as well as their impact on food quality, is crucial for optimizing their use and achieving desired results in your food processing operations. So, whether you are grinding spices, herbs, grains, or other food ingredients, make sure to choose the right industrial grinder and maintain it properly to ensure efficient and safe food processing.

The food processing industry plays a crucial role in our daily lives by ensuring that the food we consume is safe, nutritious, and readily available. One of the key components of this industry is the use of industrial grinders. These powerful machines are designed to process food ingredients into various forms, ranging from powders and pastes to emulsions and suspensions. In this article, we will take a closer look at the benefits of using industrial grinders in the food processing industry.

1. Enhanced Efficiency

Industrial grinders are designed to efficiently process large quantities of food ingredients in a short span of time. This not only saves valuable time but also increases overall productivity in food processing plants. By automating the grinding process, industrial grinders eliminate the need for manual labor, allowing workers to focus on other important tasks.

2. Consistent Quality

Consistency is essential in the food processing industry. Industrial grinders ensure that the texture, particle size, and consistency of the processed food ingredients remain uniform throughout the production process. This is crucial in maintaining the quality of the final food products and meeting consumer expectations.

3. Versatility

Industrial grinders are incredibly versatile and can handle a wide range of food ingredients. From fruits and vegetables to meat and spices, these machines are capable of grinding various types of ingredients. This versatility allows food processing plants to produce a diverse range of products, catering to different consumer preferences.

4. Waste Reduction

Food waste is a significant concern in the food processing industry. Industrial grinders play a crucial role in reducing waste by effectively grinding and utilizing every part of the food ingredient. By minimizing waste, food processing plants can not only improve their sustainability practices but also reduce expenses associated with waste disposal.

5. Improved Safety

Industrial grinders are designed with safety in mind. These machines are equipped with various safety features, such as emergency stop buttons and protective covers, to ensure the well-being of workers. Additionally, industrial grinders eliminate the risk of contamination by grinding food ingredients in enclosed and sanitary environments.

An industrial grinder is a heavy-duty machine specifically designed for commercial use in the food processing industry. Unlike household grinders, industrial grinders are capable of withstanding high volumes of grinding and are built to withstand the rigorous demands of a production environment. These machines are typically equipped with powerful motors, sharp blades, and sturdy construction materials to ensure optimal performance and longevity.

Industrial grinders are available in various sizes and configurations to cater to different processing needs. Some common types of industrial grinders used in the food processing industry include:

– Rotary Grinders: Utilize rotating shafts with blades to effectively grind food ingredients. These grinders are commonly used for grinding meat and other solid ingredients.

– Hammer Mills: Utilize high-speed rotating hammers to pulverize food ingredients into fine powders. Hammer mills are often used for grinding grains, spices, and dried herbs.

– Colloid Mills: Utilize high-speed rotor and stator assemblies to emulsify, disperse, and grind food ingredients into fine pastes and suspensions. Colloid mills are commonly used for processing nut butters, sauces, and dressings.

An industrial food grinder is a specific type of industrial grinder designed for processing food ingredients. These machines are specially engineered to meet strict food safety standards and possess features that enhance food processing efficiency. Industrial food grinders are widely used in food processing plants, restaurants, and commercial kitchens.

Industrial food grinders offer numerous benefits over traditional household grinders, such as:

– Large Capacity: Industrial food grinders are capable of processing large quantities of food ingredients at once, making them ideal for commercial use where high production volumes are required.

– Speed and Efficiency: Industrial food grinders are equipped with powerful motors and sharp blades, allowing for efficient and rapid grinding of food ingredients.

– Durability: Industrial food grinders are built to withstand heavy usage and are constructed using durable materials, ensuring long-lasting performance even in demanding environments.

– Food Safety: Industrial food grinders are designed to meet strict food safety regulations, ensuring that processed food ingredients are free from contamination and safe for consumption.

In conclusion, industrial grinders play a crucial role in the food processing industry by enhancing efficiency, maintaining consistent quality, offering versatility, reducing waste, and improving safety. These powerful machines are used to process a wide range of food ingredients, ensuring that the final food products meet consumer expectations. Industrial grinders, including industrial food grinders, are specifically designed for commercial use and are equipped with features that enhance food processing efficiency and safety. By utilizing industrial grinders, the food processing industry can achieve higher productivity, reduce waste, and deliver high-quality food products to consumers.