The food processing industry plays a crucial role in our daily lives by ensuring that the food we consume is safe, nutritious, and readily available. One of the key components of this industry is the use of industrial grinders. These powerful machines are designed to process food ingredients into various forms, ranging from powders and pastes to emulsions and suspensions. In this article, we will take a closer look at the benefits of using industrial grinders in the food processing industry.

1. Enhanced Efficiency

Industrial grinders are designed to efficiently process large quantities of food ingredients in a short span of time. This not only saves valuable time but also increases overall productivity in food processing plants. By automating the grinding process, industrial grinders eliminate the need for manual labor, allowing workers to focus on other important tasks.

2. Consistent Quality

Consistency is essential in the food processing industry. Industrial grinders ensure that the texture, particle size, and consistency of the processed food ingredients remain uniform throughout the production process. This is crucial in maintaining the quality of the final food products and meeting consumer expectations.

3. Versatility

Industrial grinders are incredibly versatile and can handle a wide range of food ingredients. From fruits and vegetables to meat and spices, these machines are capable of grinding various types of ingredients. This versatility allows food processing plants to produce a diverse range of products, catering to different consumer preferences.

4. Waste Reduction

Food waste is a significant concern in the food processing industry. Industrial grinders play a crucial role in reducing waste by effectively grinding and utilizing every part of the food ingredient. By minimizing waste, food processing plants can not only improve their sustainability practices but also reduce expenses associated with waste disposal.

5. Improved Safety

Industrial grinders are designed with safety in mind. These machines are equipped with various safety features, such as emergency stop buttons and protective covers, to ensure the well-being of workers. Additionally, industrial grinders eliminate the risk of contamination by grinding food ingredients in enclosed and sanitary environments.

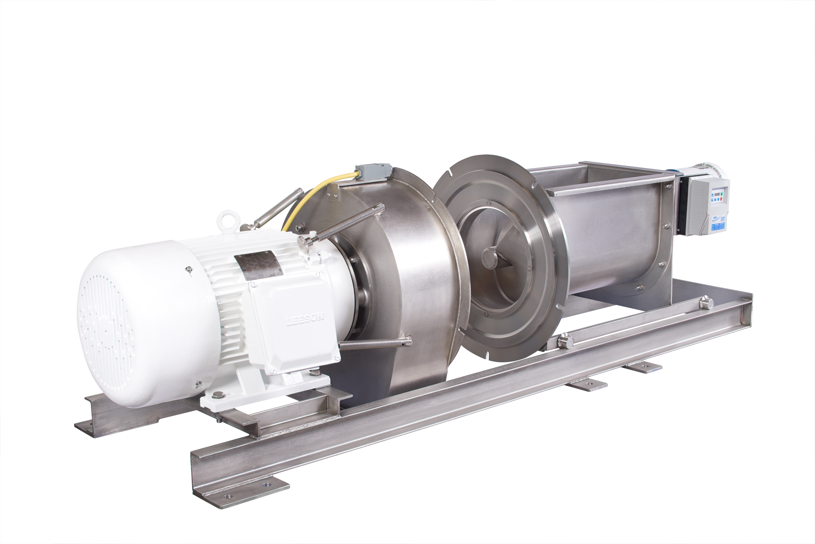

An industrial grinder is a heavy-duty machine specifically designed for commercial use in the food processing industry. Unlike household grinders, industrial grinders are capable of withstanding high volumes of grinding and are built to withstand the rigorous demands of a production environment. These machines are typically equipped with powerful motors, sharp blades, and sturdy construction materials to ensure optimal performance and longevity.

Industrial grinders are available in various sizes and configurations to cater to different processing needs. Some common types of industrial grinders used in the food processing industry include:

– Rotary Grinders: Utilize rotating shafts with blades to effectively grind food ingredients. These grinders are commonly used for grinding meat and other solid ingredients.

– Hammer Mills: Utilize high-speed rotating hammers to pulverize food ingredients into fine powders. Hammer mills are often used for grinding grains, spices, and dried herbs.

– Colloid Mills: Utilize high-speed rotor and stator assemblies to emulsify, disperse, and grind food ingredients into fine pastes and suspensions. Colloid mills are commonly used for processing nut butters, sauces, and dressings.

An industrial food grinder is a specific type of industrial grinder designed for processing food ingredients. These machines are specially engineered to meet strict food safety standards and possess features that enhance food processing efficiency. Industrial food grinders are widely used in food processing plants, restaurants, and commercial kitchens.

Industrial food grinders offer numerous benefits over traditional household grinders, such as:

– Large Capacity: Industrial food grinders are capable of processing large quantities of food ingredients at once, making them ideal for commercial use where high production volumes are required.

– Speed and Efficiency: Industrial food grinders are equipped with powerful motors and sharp blades, allowing for efficient and rapid grinding of food ingredients.

– Durability: Industrial food grinders are built to withstand heavy usage and are constructed using durable materials, ensuring long-lasting performance even in demanding environments.

– Food Safety: Industrial food grinders are designed to meet strict food safety regulations, ensuring that processed food ingredients are free from contamination and safe for consumption.

In conclusion, industrial grinders play a crucial role in the food processing industry by enhancing efficiency, maintaining consistent quality, offering versatility, reducing waste, and improving safety. These powerful machines are used to process a wide range of food ingredients, ensuring that the final food products meet consumer expectations. Industrial grinders, including industrial food grinders, are specifically designed for commercial use and are equipped with features that enhance food processing efficiency and safety. By utilizing industrial grinders, the food processing industry can achieve higher productivity, reduce waste, and deliver high-quality food products to consumers.