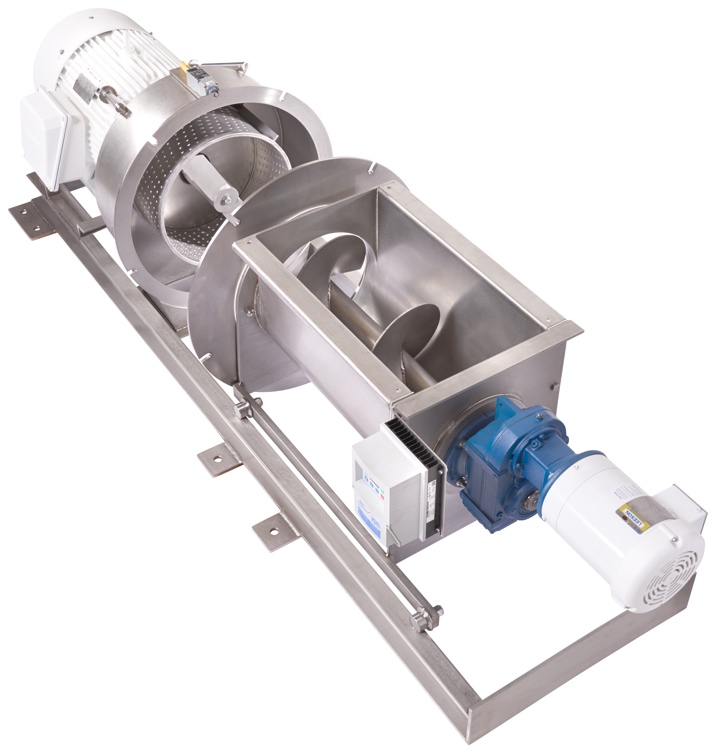

Corenco’s new screw-fed disintegrators address customers’ difficulties feeding products into the standard angle disintegrator. Feeding issues generally accompany bulky products that have high adhesion, such as dried fruit, and products that have high buoyancy (high surface area and low bulk density) such as paper, bark, leafy greens, and styrofoam.

An additional obstacle to feeding occurs when the product goes through a washing step before milling, creating surface tension.

Corenco’s screw-fed disintegrators replaced random gravity feeding with precise auger feeding, overcoming the second set of obstacles by “force feeding”. Added benefits include a metered feed into the mill, which improves milling efficiency by limiting surging, protecting against overload, and thus providing a more modular, stand alone piece of equipment.

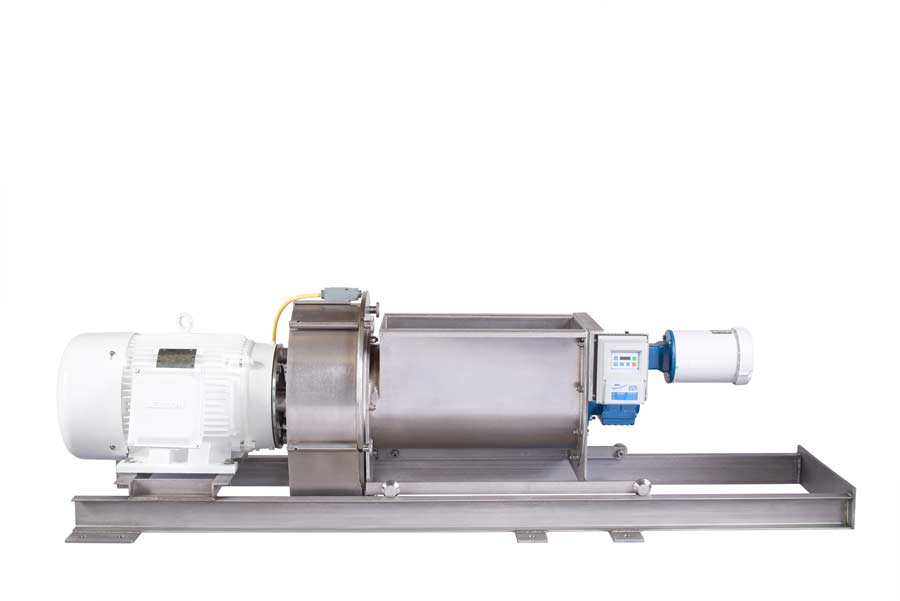

50 Horsepower

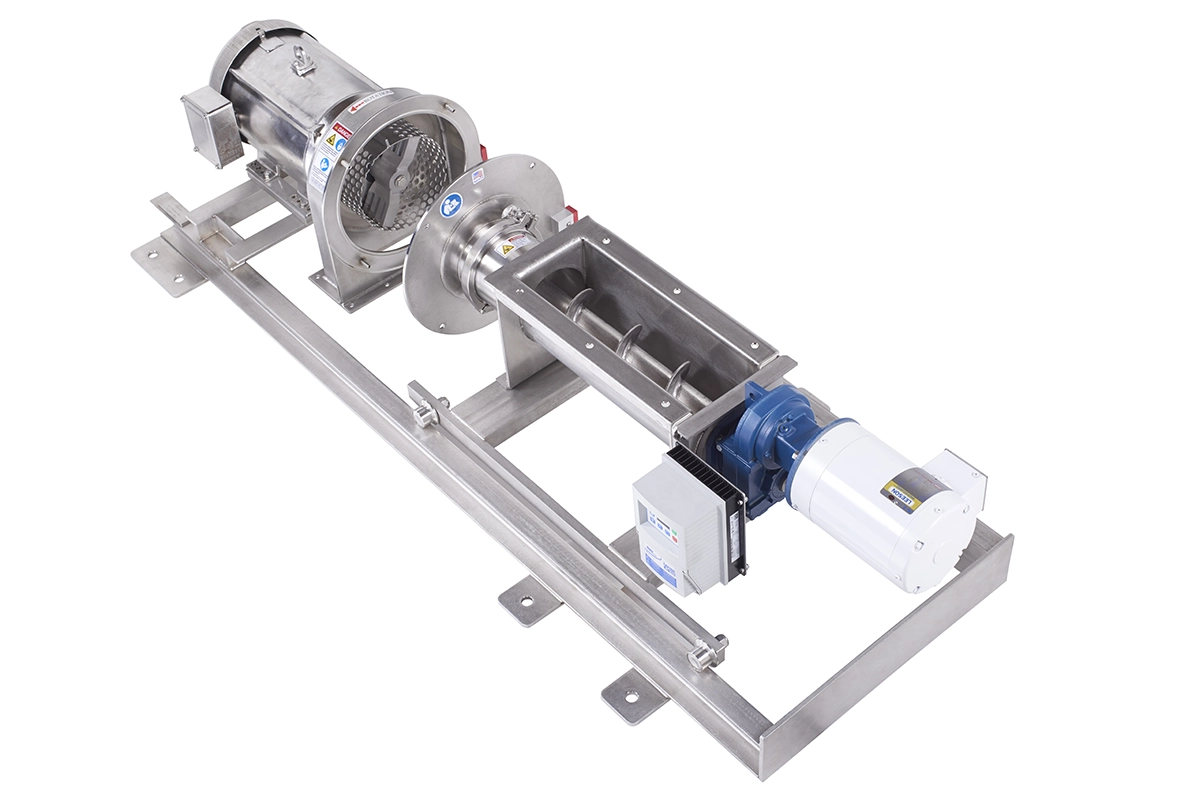

20 Horsepower

10 Horsepower